Prototypes & Production

Fast, precise prototyping for flawless product development, ensuring accuracy, efficiency, and seamless production.

Rapid Prototyping

Prototyping in PCB manufacturing is essential for validating design and performance before full production. It helps identify errors, test power, components, and RF performance, and ensures the design meets application needs and compliance standards, avoiding costly delays and rework.

Our rapid prototyping services will significantly improve your production yield.

Low-Volume Production

Production Quality

Mock-Ups

Small Quantity

Rapid Prototyping

Cosmetic Prototypes

Configurations

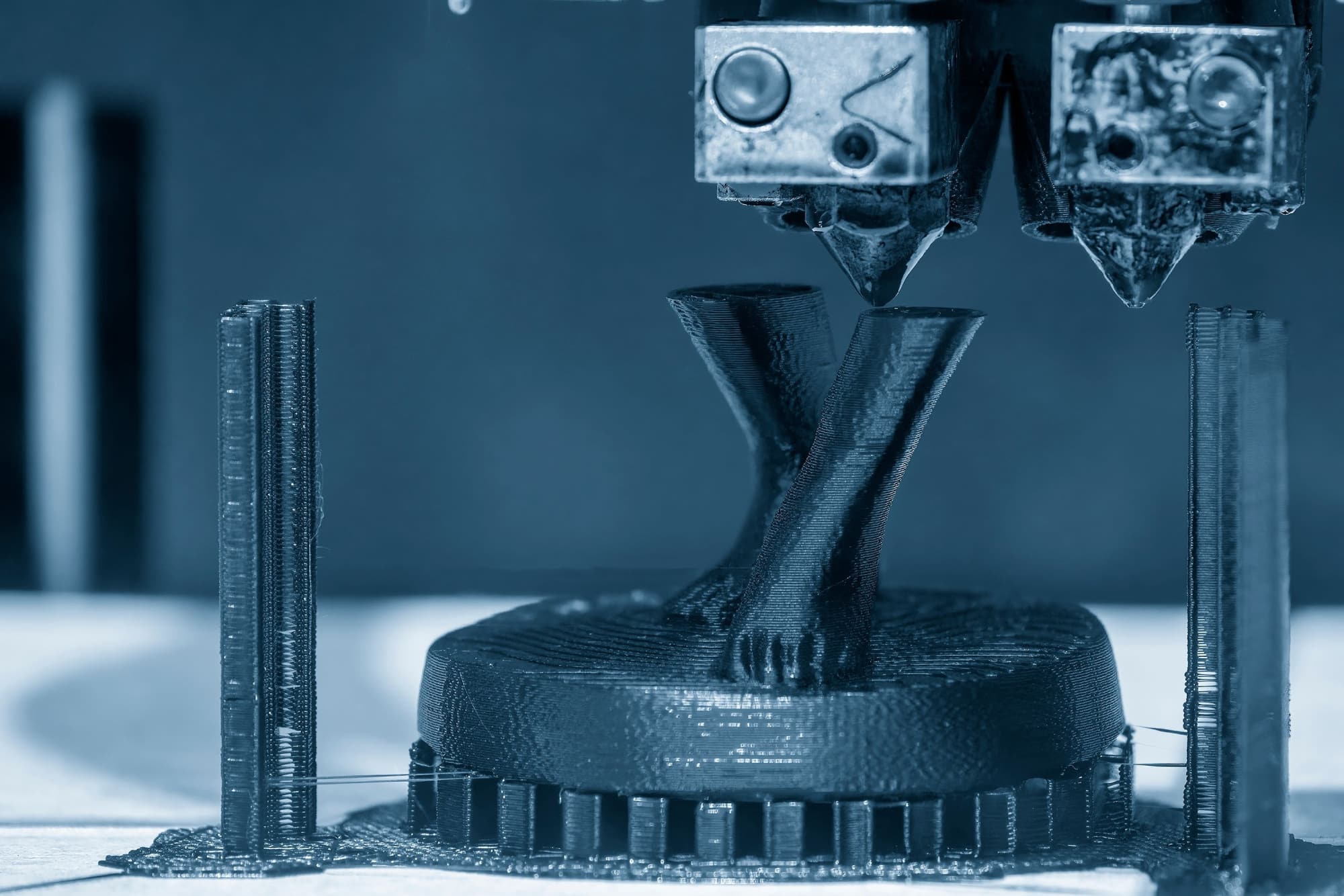

3D Printing

3D printing creates precise, complex parts from CAD files, reducing waste and ensuring strong mechanical properties. We offer quick, reliable prototypes and production parts with high accuracy, using quality materials and advanced software. Our expert team can print your CAD design with fast turnaround, often in one day.

Our Services and Capabilities

Selective Laser Sintering (SLS)

SLS 3D printing uses high-powered lasers to fuse together particles of plastic, metal, or ceramic powder, resulting in a 3D object. This method is significantly stronger than other additive manufacturing methods, as the particles are fused together to form a single, solid object, making it more durable and able to withstand real-world testing without becoming brittle over time.

MultiJet Fusion (MJF)

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

ColorJet Printing (CJP)

Carbon Digital Light Synthesis (DLS)

Polyjet

Direct Metal Laser Sintering (DMLS)

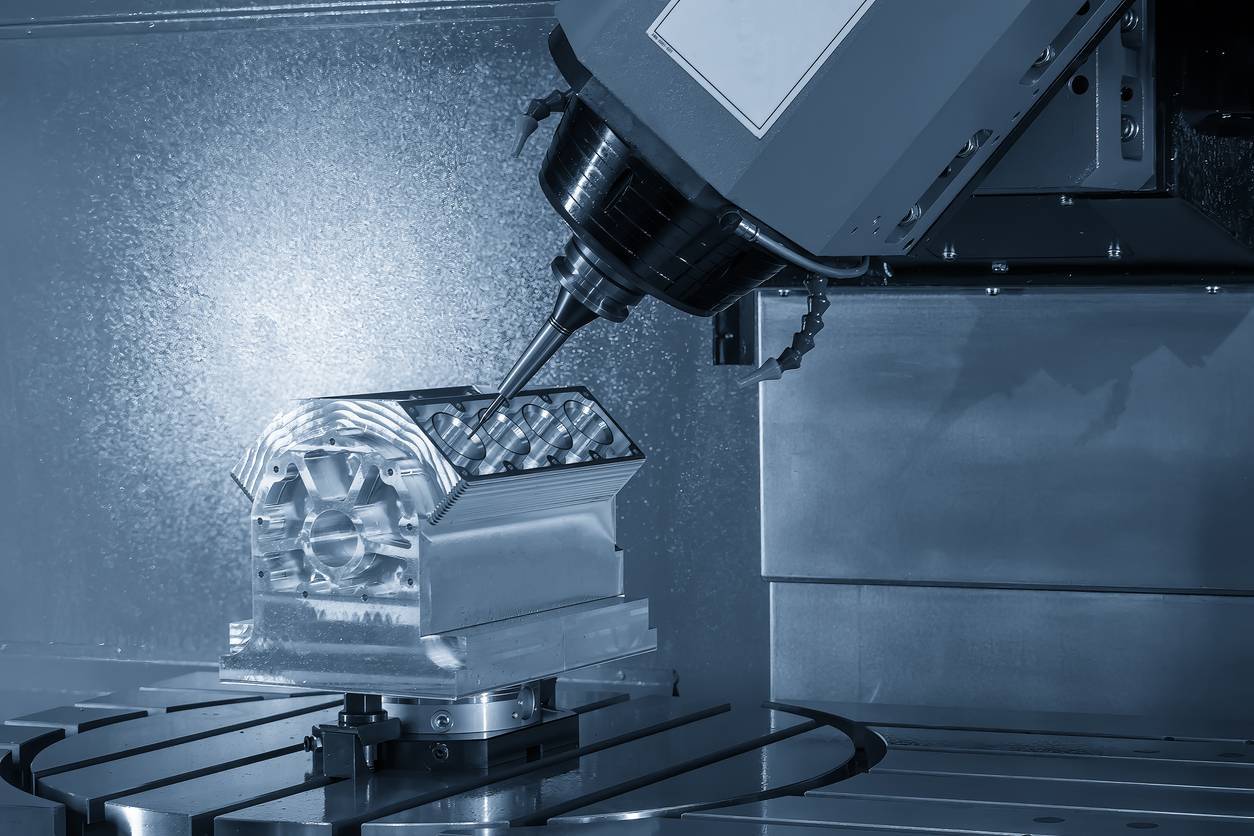

CNC Machining

Computer Numerical Control (CNC) machining is a process used to control machine tools with highly accurate programmed commands. It is used to produce parts with complex shapes and features, as well as components with tight tolerances and complex geometries. We understand that each customer has different needs, and utilize a range of machining methods to ensure that we can provide the most efficient and accurate solutions for any scale of project. Our wide range of CNC mills and turning centers allow us to work with a variety of materials and achieve a high degree of accuracy and precision.

We provide instant access to a global network of machine shops that can fulfill your orders quickly and efficiently. Our commitment to providing a single point of contact for our customers makes it easy to benefit from consolidated orders and the efficiency of our partner shops – all without the hassle of managing multiple orders.

Injection Molding

Injection molding produces durable plastic parts for high-volume runs by injecting molten thermoplastic into a metal mold. Send us your CAD file, work with our engineers to refine the design, and proceed to production. Specify finishing and inspection needs, and we’ll package and ship your parts when ready.

Plastic injection molding

Liquid silicone rubber molding

Over-molding

Insert molding

Multi-cavity / Family molds

Production Packages

Comprehensive manufacturing and testing suites are essential for evaluating product performance during and after production. These packages provide the data needed to assess both the product and process, along with documentation to ensure the product meets all standards and specifications for customer approval.

Product Requirement details

Gerber files

ODB++ files

Assembly drawings

Pick and place files

PCB Parasolid, DXF, and .STEP files

System validation and verification file

Manufacturing jigs

Product test suites

We're Here To Help!

Headquarters

Electronics4All

250 Herzberg Road

Ottawa, ON K2K 2A1

Lab Testing Facility

Hours

Monday – Friday: 8:30AM – 5PM EST

Saturday – Sunday: Closed