Manual & Machine Assembly

Precision Assembly for Faster Prototyping and Seamless Integration.

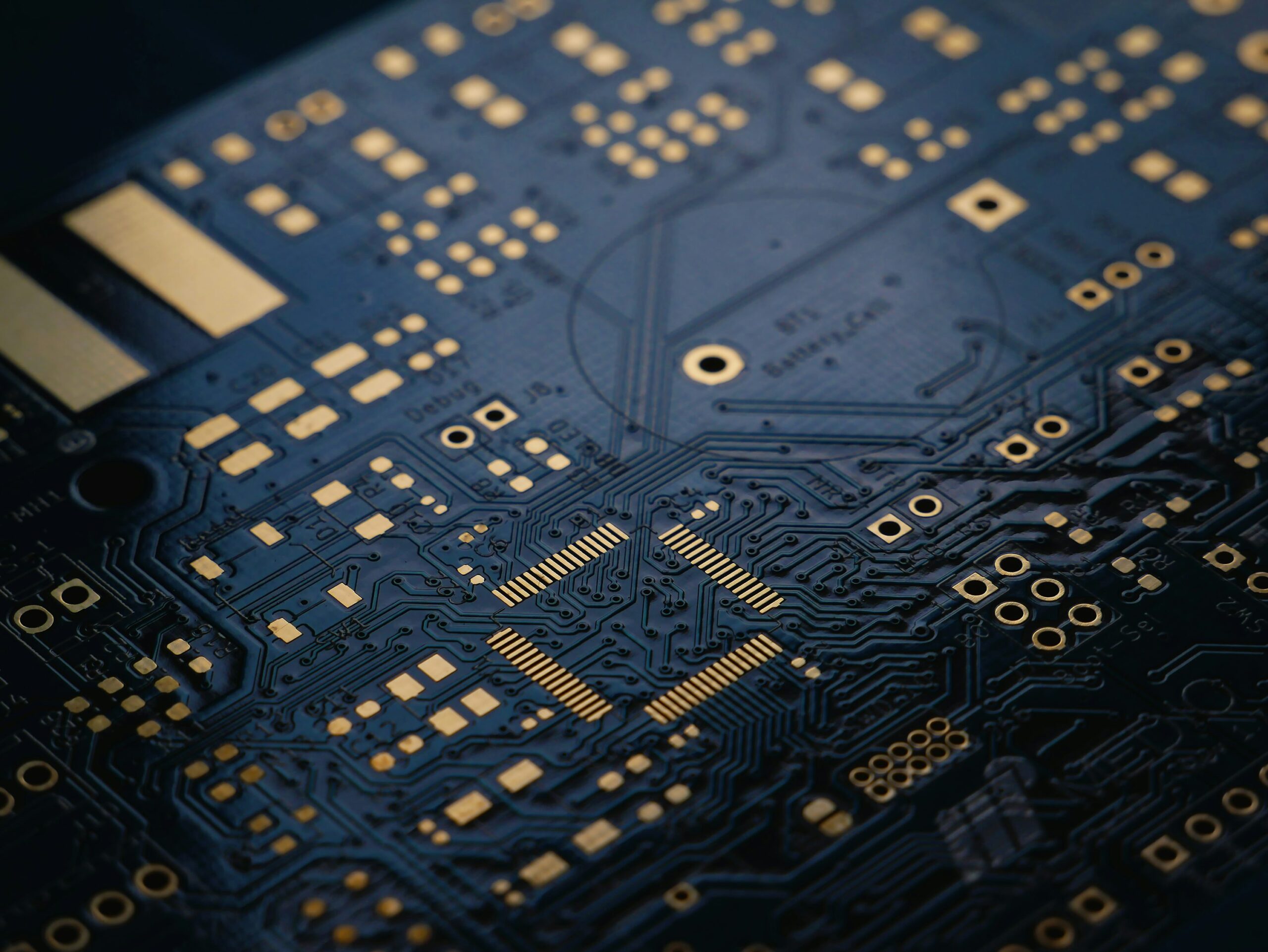

PCB Assembly

We provide both manual and machine PCB assembly to support your needs. Our IPC-certified technicians hand-place components for small prototype runs, helping validate designs efficiently. Manual assembly speeds up prototyping by reducing component requirements, eliminating chip-shooter programming, and avoiding production line scheduling conflicts, saving both time and cost.

Assembly in 24 hours

IPC certified assemblers

Single board assemblies

Configuration builds

Express delivery

Electromechanical Assembly

We have the capability to design products and provide turnkey assemblies that incorporate mechanical, electrical, and electro-mechanical components. We can also run automated test suites to validate the quality of the produced products. This allows us to provide a complete solution to our customers, from design to delivery.

Save time and resources

Our team handles the entire supply chain including procurement of materials, assembly, quality testing, documentation, and delivery of the electromechanical assembly to our client.

Quality that you can trust

We provide consistently high-quality assemblies that you can trust, enabling your team to focus on business expansion and sales. Our team will plan the manufacturing and assembly process, while not losing sight of both cost efficiency and quality.

Electronics4All is an ISO 9001:2015 certified company, which demonstrates our commitment to providing high quality services for our clients.

Supply chain network

Our existing and expanding supply chain network of trusted partners enables us to commit to fast and efficient delivery. Even for the toughest quality and time requirements, we have a solution for that too.

We also offer machine component placement

Surface Mount (SMD) Component Placement

Dedicated high volume machines for fast turn-around

Low to medium production builds

Custom test equipment

Competitive pricing

Benefits of Hand Placement

- Solder through-hole components without product delay

- High accuracy of component placement, assembled to IPC-610 Standards

- Does not depend on production line availability

- Avoid defects which can occur when using semi-automatic equipment

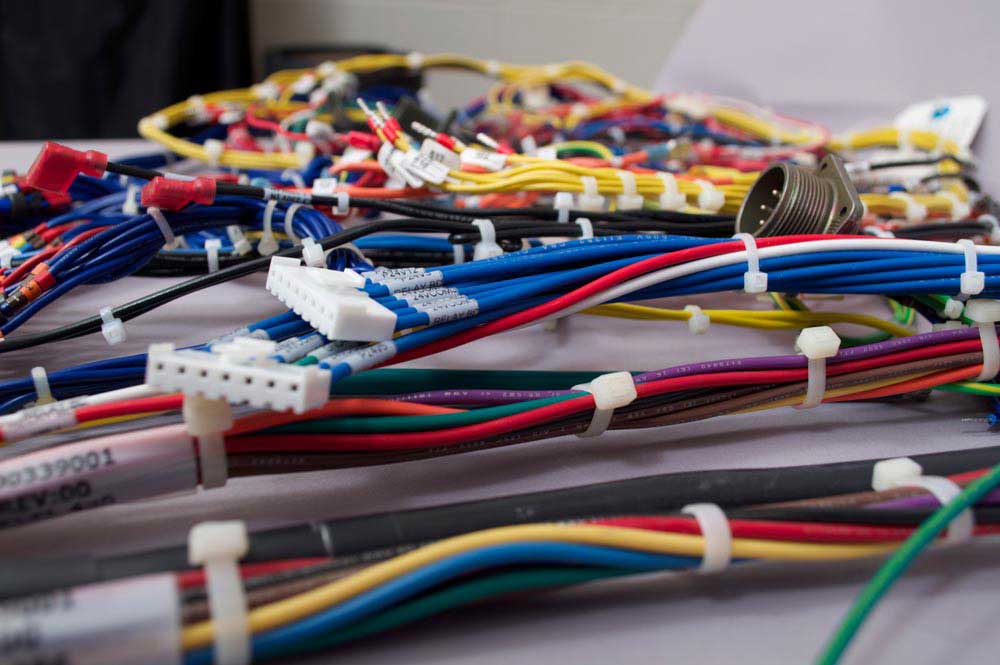

Wire Harness Assembly

Non-Engineering hand sketch

2D drawing

3D models

Detailed product specifications

Physical sample

There is an endless variety of cable harness configurations available. Electronics4All’s experts can custom design and build your harness with any of the following inputs:

5 Main Steps in Wire Harness Assembly

Whether your wire harness has 5 wires or 100 wires, the assembly process typically follows the steps outlined below:

Wire Cutting and Labelling

The wires are first cut to the desired length indicated on the design and labeled appropriately. Proper labeling is a critical step in this process.

Wire Termination

The end of each wire is stripped to expose the uninsulated conductor and fitted with the required connectors and terminals.

Wire Assembly.

Wires and components are assembled and bound together based on the specification outlined in the design.

Wire Testing

The harness is tested for electrical functionality. This testing is done with the aid of a pre-programmed test board that checks for faults in the completed harness.

Embed Logo

The final step of the assembly process is to embed tags with your company logo or add text to the wire harness for a professional look.

We're Here To Help!

Headquarters

Electronics4All

250 Herzberg Road

Ottawa, ON K2K 2A1

Lab Testing Facility

Hours

Monday – Friday: 8:30AM – 5PM EST

Saturday – Sunday: Closed