Prototypes and Production

Prototypes and Production

Rapid Prototyping

Our rapid prototyping services will significantly improve your production yield.

It is essential that the prototyping phase in PCB manufacturing is performed as the first step in the manufacturing process. This critical activity allows designers and manufacturers to validate the design and rectify any design errors prior to proceeding into the production stage. This includes power up testing, power consumption measurement, component placement, RF performance, verification of critical measurements, and overall electrical performance of the board. Prototyping also helps to ensure that the design is suitable for the intended application, it meets all the performance requirements, and can be used for pre-certification compliance testing prior to committing to a full production build. All of these efforts up front will save significant costs associated with rework and schedule delays that would incur if this critical step is overlooked.

Mock-Ups

Mock-ups provide a realistic representation of how a product will look and feel, allowing designers to make informed decision about the design and materials used. They also serve as visual aids to potential investors without the need to secure large amounts of funding early in the product cycle.

Production Quality

Cosmetic prototypes are used to evaluate the product's aesthetic design, ergonomics, and overall form factor, and enable engineers to observe how people interact with the product.

Rapid Prototyping

3D printing, CNC machining to create physical parts or models quickly and cost-effectively. It allows designers and engineering to test ideas, test fit and functionality, and make design modifications.

Low-Volume Production

Low-volume production builds are small scale, limited runs designed to test the market before committing to large scale production. They are often used to test product features, performance, and market demand, usually not exceeding 100,000 units.

Cosmetic Prototypes

Cosmetic prototypes are used to evaluate the product's aesthetic design, ergonomics, and overall form factor, and enable engineers to observe how people interact with the product.

Configurations

Configuration prototypes enable population of different components on the same PCB to assess performance and risk of a particular bill of material configuration.

Small Quantity

By building a small quantity of prototypes at the initial stage, it is simpler to alter the design to meet the needs of the evolving market quickly and efficiently without making a large investment upfront.

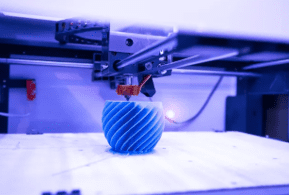

3D Printing

3D printing is a technology that uses a computer-aided design (CAD) file to create three-dimensional objects. Typically this is achieved through an additive process, where successive layers of material are generated to create complex shapes that would be difficult and expensive to create with traditional manufacturing methods. 3D printing is a very precise and efficient process, it minimizes material wastage, enabling the production of parts with highly detailed surface finishes and excellent mechanical properties. Our 3D printing services provide superior accuracy and repeatability, allowing us to create prototypes and production parts quickly and reliably. This is achieved by utilizing high-quality materials and precise temperature and pressure controls, as well as advanced software that ensures the most accurate controls. This guarantees that the parts we create are identical, even when produced in larger quantities. Our team of experienced industrial design engineers can work with you to create a 3D model that meets your exact specification, or you can simply provide us with your 3D CAD model and we will create a unique 3D print as quick as 1 day turnaround.

Our Services and Capabilities

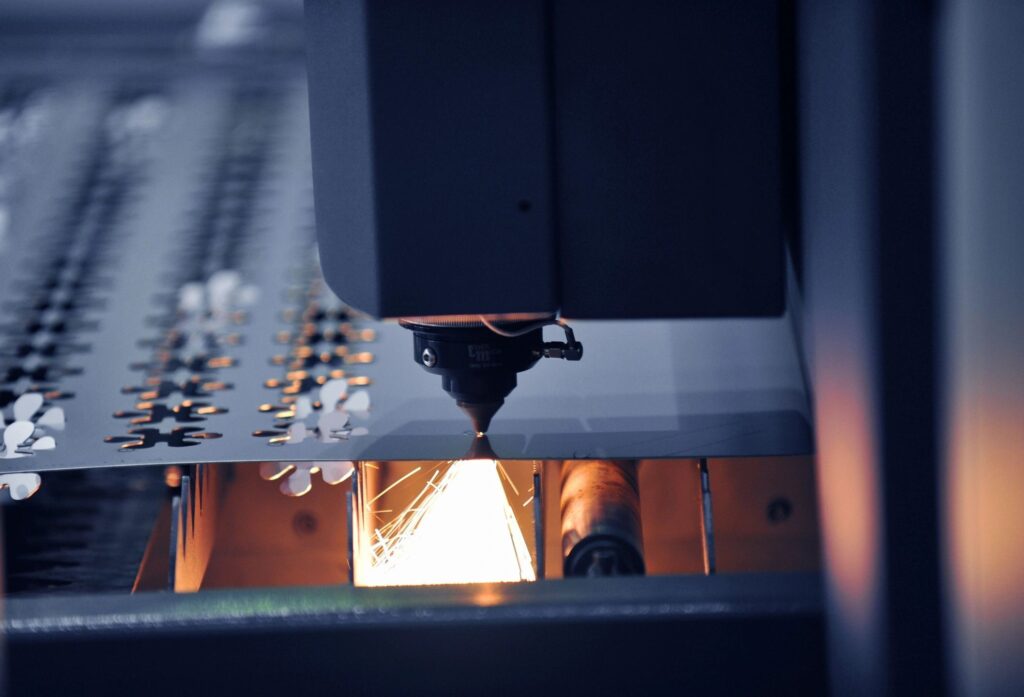

SLS 3D printing uses high-powered lasers to fuse together particles of plastic, metal, or ceramic powder, resulting in a 3D object. This method is significantly stronger than other additive manufacturing methods, as the particles are fused together to form a single, solid object, making it more durable and able to withstand real-world testing without becoming brittle over time.

MJF 3D printing is a process that can produce high-quality parts at relatively low cost and at faster speed that other processes such as SLS and SLA. MJF enables the production of complex geometries, with intricate internal structures, that can be produced in a single piece.

MJP also known as Material Jetting is a process that works by sequentially depositing small droplets of material onto a build platform to create a 3D object. This process is highly accurate, allowing for very detailed parts with smooth surfaces and intricate geometries.

FDM uses a thermoplastic filament which is melted and extruded to create a 3D object layer by layer. This process is known for speed, accuracy, and low cost compared to other 3D printing methods, and allows parts to be made directly from 3D CAD to thermoplastic materials without tooling.

SLA 3D printing can produce parts with fine details and tight tolerances, making them highly accurate and an excellent choice for creating prototypes. These parts are highly durable, making them suitable for testing, snap-fit assemblies, mechanical measurement verification, and end-use applications.

CJP 3D printing technology uses a range of colored powder materials to create full-colour 3D models in a single build. The technology utilizes a binder to adhere and fuse the powder layers together to produce a smooth, glossy finish. This technology is well-suited for prototypes and concept, and demonstration models as it allows for fast, cost-effective prints with vibrant color.

Carbon DLS uses light and oxygen to create parts with complex geometries, superior properties and performance such as strength and stiffness, and intricate surface details. This process eliminates the need for molds, tooling, and other traditional manufacturing methods.

Ployjet 3D printing uses a liquid photopolymer to produce highly accurate parts with smooth surfaces and intricate details. This method enables producing multi-colored and multi-material parts in one build.

DMLS is a method of manufacturing that is also known as selective laser melting, laser powder bed fusion, and laser sintering. This method involves using a high powered laser to melt and fuse metal powder into a 3D shape. The high precision of DMLS makes it suitable for both prototyping and production end-use of complex metal parts for medical, automotive, and industrial applications.

CNC Machining

Computer Numerical Control (CNC) machining is a process used to control machine tools with highly accurate programmed commands. It is used to produce parts with complex shapes and features, as well as components with tight tolerances and complex geometries. We understand that each customer has different needs, and utilize a range of machining methods to ensure that we can provide the most efficient and accurate solutions for any scale of project. Our wide range of CNC mills and turning centers allow us to work with a variety of materials and achieve a high degree of accuracy and precision.

We provide instant access to a global network of machine shops that can fulfill your orders quickly and efficiently. Our commitment to providing a single point of contact for our customers makes it easy to benefit from consolidated orders and the efficiency of our partner shops – all without the hassle of managing multiple orders.

Injection Molding

Injection molding is used to create strong, durable plastic parts and is ideal for manufacturing projects with high volume production requirements. During the injection molding process, molten thermoplastic is injected into a metal mold and then cooled to form consistent and durable solid parts. Get your injection molding project started today. Send us your CAD file, work with our engineers to optimize your design, and move to production when you’re ready. You can specify the post-production and finishing options you need for your parts, along with any inspection requirements. When your order is ready, we’ll package and ship the finished parts to you.

Capabilities

- Plastic injection molding

- Liquid silicone rubber molding

- Over-molding

- Insert molding

- Multi-cavity / Family molds

Production Packages

Complete manufacturing and testing suites are critical for the success and testing of the final product during and following the manufacturing cycle. These packages provide the necessary information to evaluate the performance of the product and the manufacturing process. They also provide the necessary documentation for the end customer to confirm all the required standards and specification have been met to approve the product.

Production Package Contents

- Product Requirement details

- Gerber files

- ODB++ files

- Assembly drawings

- Pick and place files

- PCB Parasolid, DXF, and .STEP files

- System validation and verification file

- Product test suites

- Manufacturing jigs